Engineering Solutions You Need for Your Product

“Engineering, when done well, is revealed by elegance of design”

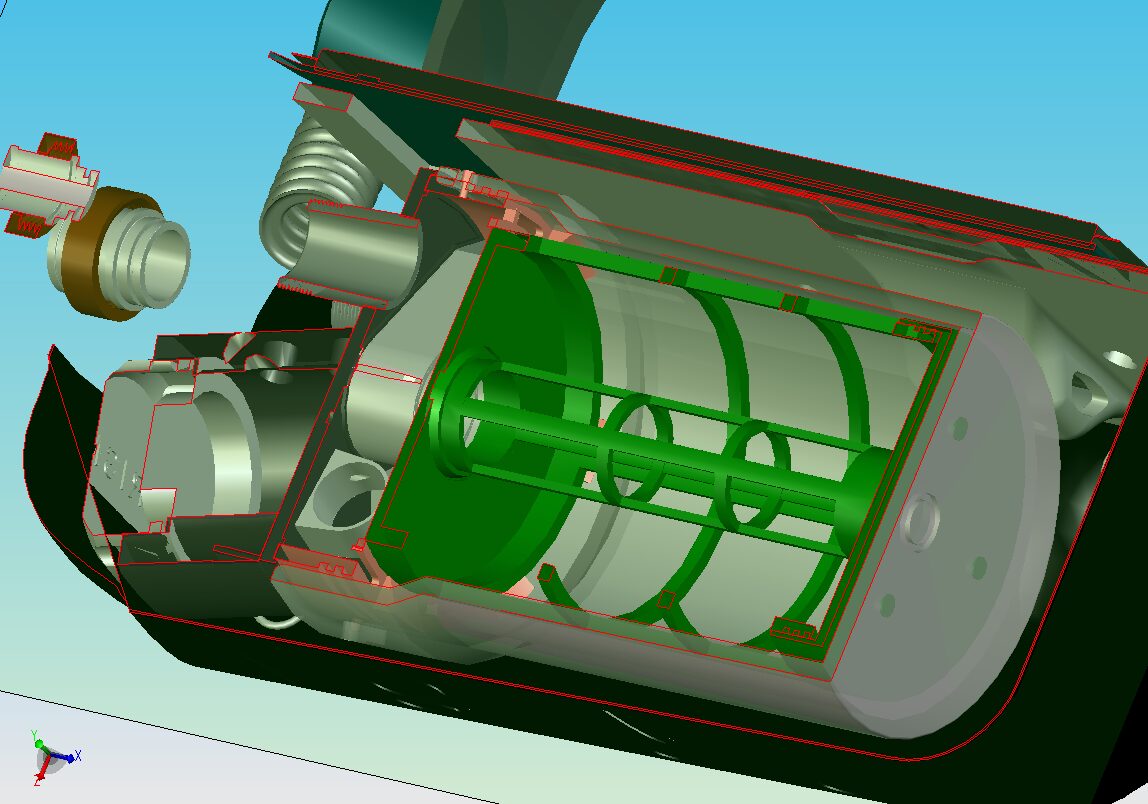

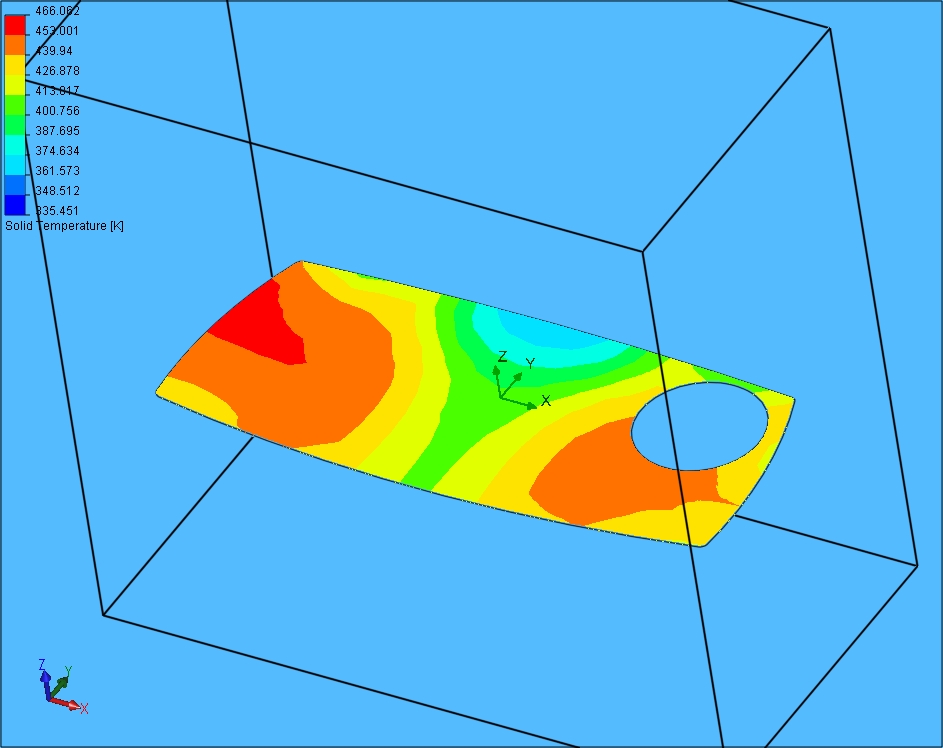

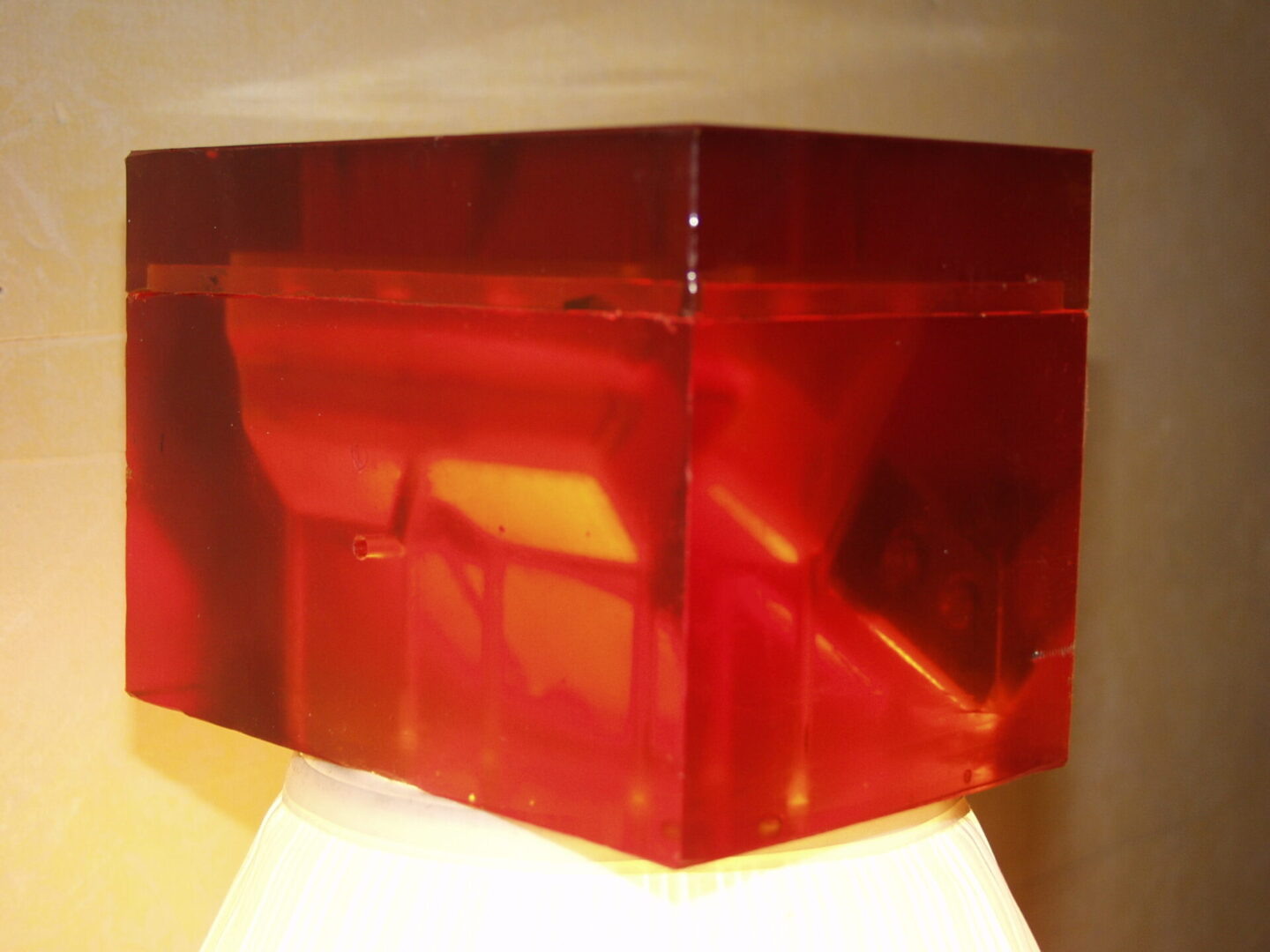

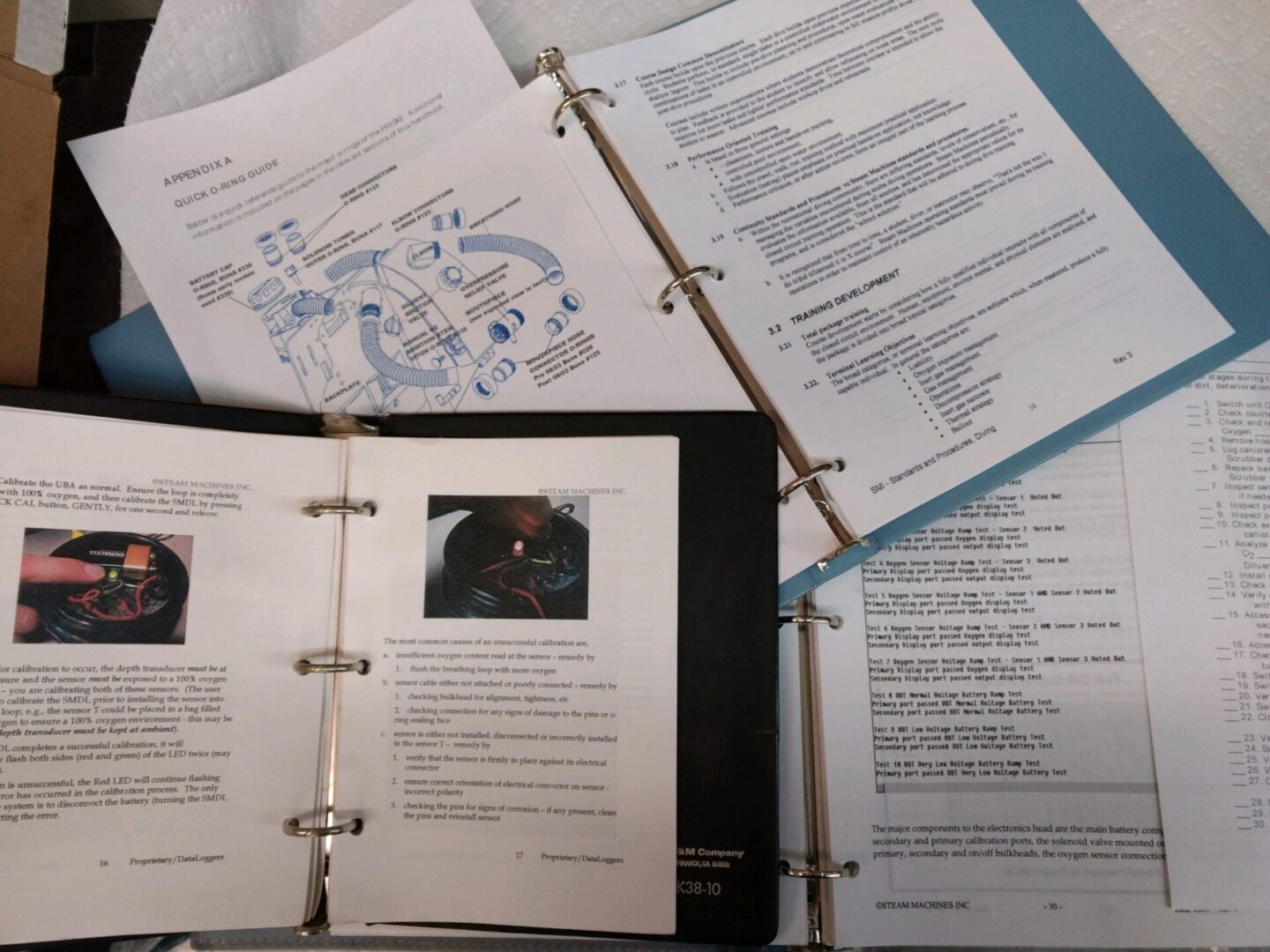

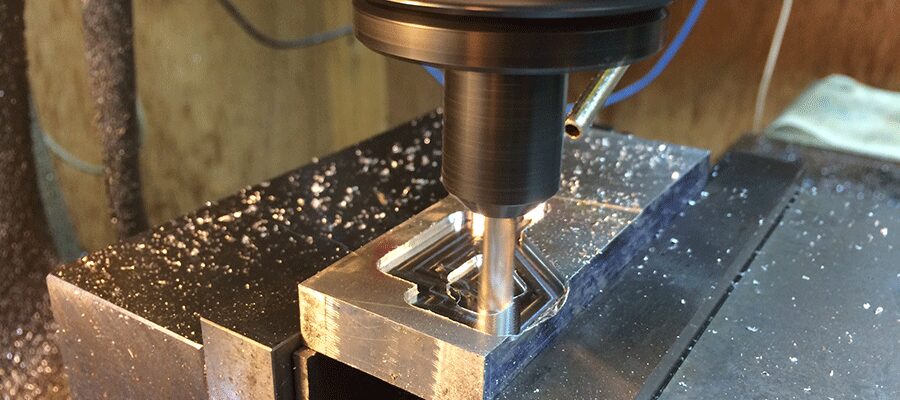

SMI provides a full range of design and production support services; everything you need to take your idea from concept to completion and all the little things in-between…